Thermic fluid heaters are very efficient equipment used in process heating and it uses high viscous synthetic oil as a heating medium. Process Industry can achieve the maximum process heat temperature with low pressure in a Thermic fluid heater. Thermic fluid heaters are usually preferred because if we use the steam boiler for high temperatures then it would increase the overall cost of the project.

Thermic Fluid Heater Comprises of following:

- Heater coils

- Burner/Furnace

- Expansion cum Deaerator tank

- Air-cooled, Circulating oil pump with mechanical seal suitable for high temperatures

- Primary and secondary fans (Depends on fuels)

- Heat recovery units

- Pollution control equipment (Includes only with solid fuel fired systems)

- Chimney for stack dispersal

- Control panel for ease of operation

Types of Thermic Fluid Heater

The thermic fluid heater is the most common process heating machine. The thermic fluid heaters can be classified on the basis of fuel types. Here, we have mentioned all the thermal fluid heaters that are used in the industries,

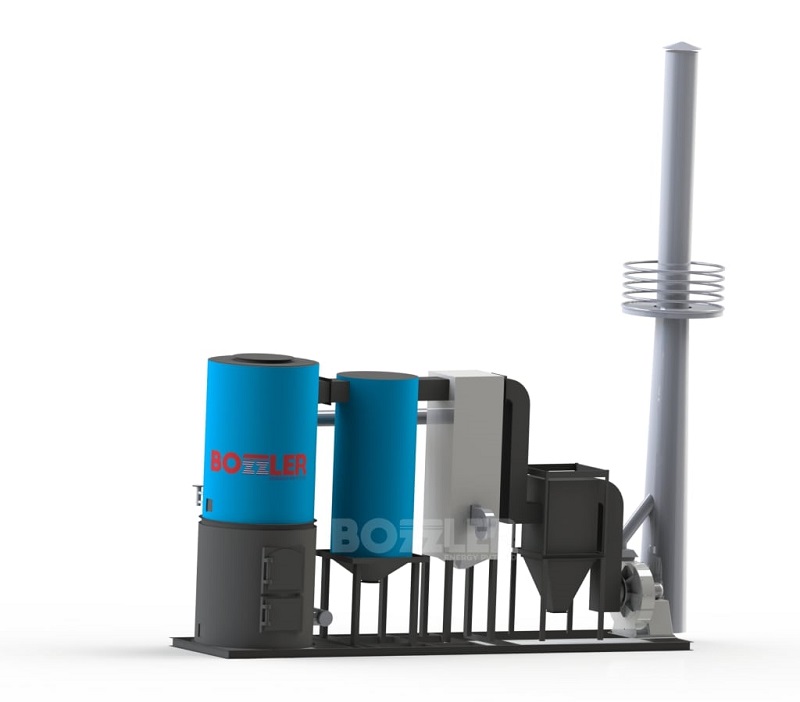

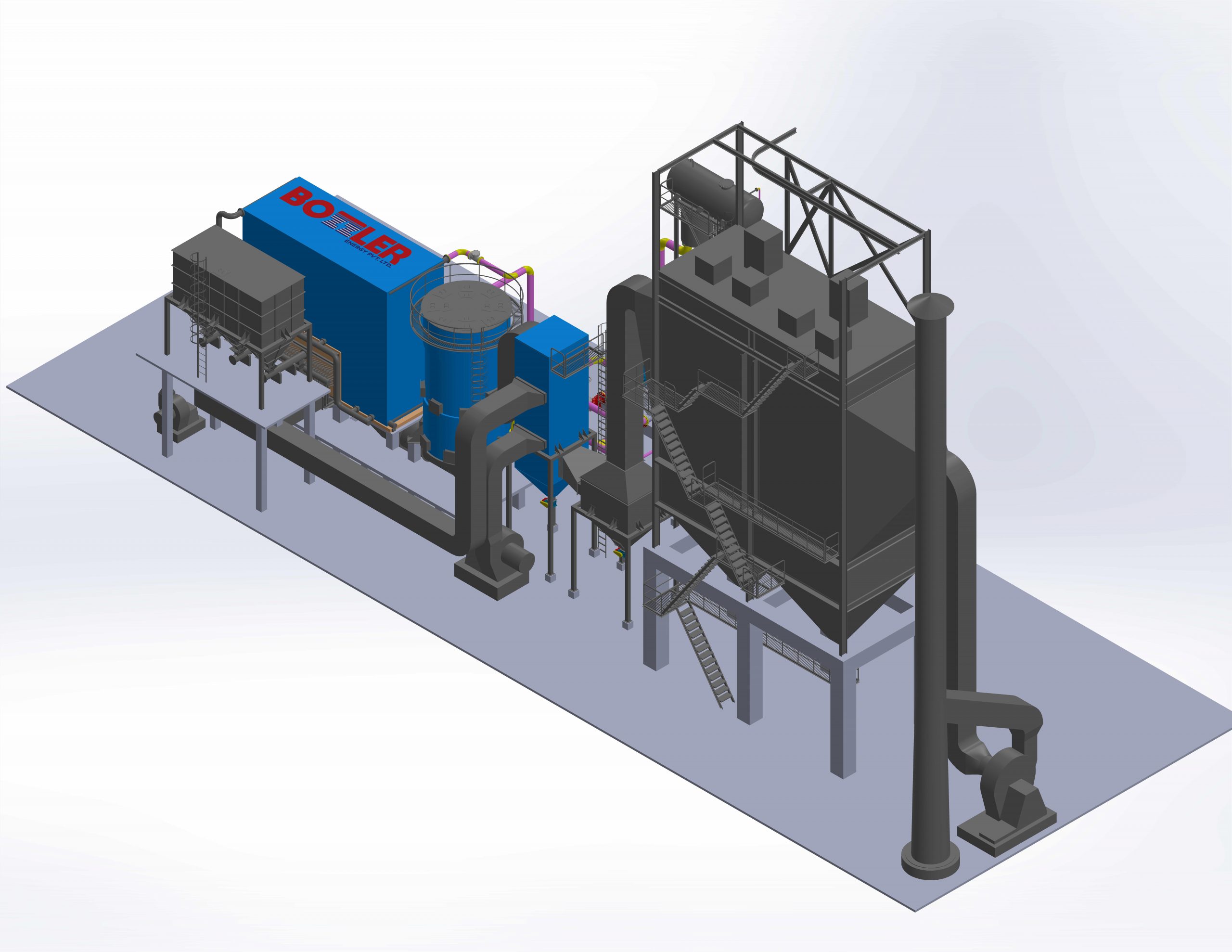

1) Solid Fuel Fired

As per modern industry trends, to meet any manufacturing process industry’s requirements these are the following features in solid fuel fired system.

- Low Operating Cost

- Most reliable operation for constant temperature.

- Optimized electrical consumption

- High heat output with minimum fuel consumption.

- Highest safeties for hazel free operation and process optimization.

We have developed Below series of Thermic Fluid Heaters based on capacity and customer requirements:

a) BL Series

Features

- The capacity range of the BL series is from 1.0 M to 20.0 Mkcal/hr

- A 5-pass thermic fluid heater delivers almost 80% efficiency, which is the highest in the segment.

- To maximize the heat transfer it has a secondary air system in the furnace for turbulence in a draught of flue gas.

- Pollution control machines are part of the system to minimize SPM level and match the pollution control board rules.

b) BV Series

Features

- The capacity range is from 0.1 M to 1.0 Mkcal/hr.

- A three-pass thermic fluid heater provides high efficiency and compatibility.

- It offers up to 78% of efficiency.

- BV series has a rare combination of mobility and wood firing systems up to 6 lac kcal per hour.

- Very much easy to install

c) BVX Series

Features

- Capacity ranges of 0.8 to 2.5 Mkcal/hr.

- The BVX series thermic fluid heater is a next-generation 4-pass design in a single heat exchanger.

- Offers the same efficiency as the 5 pass system because of the technological upgrade.

- The BVX series has a wet back system that helps in utilizing the maximum energy generated from fuel firing.

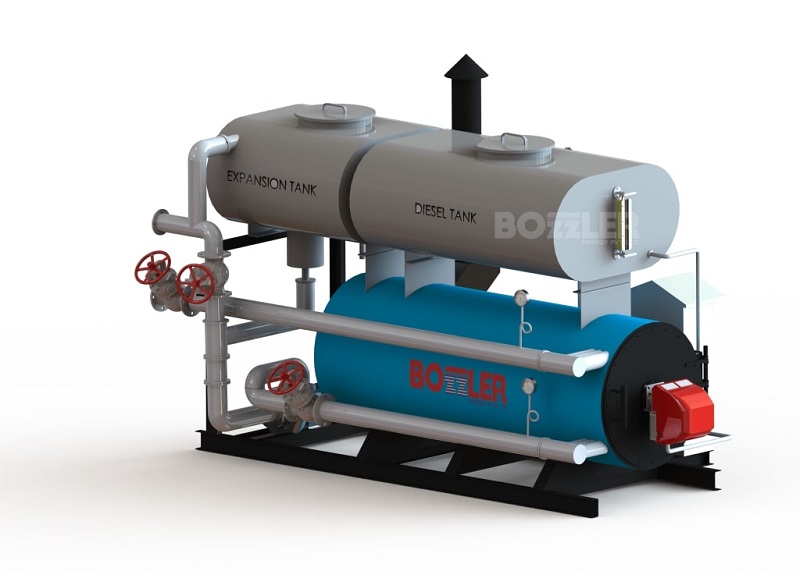

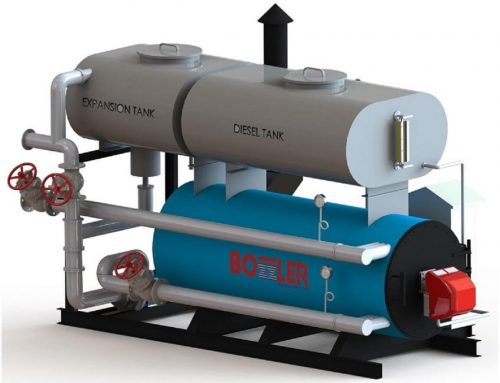

2) Fluid Fuel Fired

Features

- BH series Capacity ranges from 50 K to 20 Mkcal/hr.

- BH series provides the best in class efficiency and that is around 92 percent.

- The BH series fluid fuel-fired thermic fluid heaters are easy to maintain and provides mobility and pre-wired automation.

- This series offers compatibility with various fuels like HSD, LDO, PNG, FO, LPG, Wood Pellets, etc.

These are the types of thermic fluid heaters to use as heating equipment in industries where heat transfer is important instead of pressure.

Advantages of Thermic Fluid Heater

For the heating process, usually hot water, steam, and thermal fluid are used. Every medium has different advantages and disadvantages, and thermal fluid heaters considered as the best option.

The thermic fluid heater can cover temperature that ranges from 0° C to 400° C, whereas the standard steam system can cover the temperature that ranges from 121° C to 250° C but at very high pressure. The standard hot water can work between the temperature 0° C and 140° C.

Thermic fluid heaters are very suitable, non-pressurized, heating supply equipment that has numerous advantages as mentioned below,

1) Attain High Temperature at Low Pressure

- Decreases constant attention/regulation and monitoring of system pressure levels results in no risk of explosion

2) Low Maintenance

- The thermic fluid heater has a closed-loop system, and this reduces the maintenance cost compared to other systems.

- No water leads to no corrosion.

- The thermal fluid heaters do not need regular water treatment, daily blowdown, handhole gasket replacement, annual inspections, steam trap maintenance, or even retubing. All these things help decrease the maintenance cost of thermal fluid heaters

3) Easy to Operate

- Do not need an operator with specific education, as there is no high pressure is involved.

- As Thermic Fluid do not freezes, it does not require special arrangements.

4) Easy Installation

It is flexible because they are an indirect heating source and that is why you can install it at a remote location. A thermal fluid heater does not need freeze protection and you can install it outdoors as the installation process is simple.

5) No Need for a Licence Every Year

- As having no risk of explosion, No need to have a safety license every year

6) Less Capital and Operating Cost

- Capital investment is lesser than steam boilers and as above-mentioned advantages lead to lower operating costs too.

- No need to have licensed operators.

- No renewal of certification needed as required in IBR

These are some of the advantages of a Thermic fluid heater and why it is one of the most preferred options for industries nowadays.

Industrial Applications of Thermic Fluid Heater

The use of a thermic fluid heater is increasing in different industries as listed below,

- Road Construction Industry

- Food & Beverages Industry

- Plywood & Laminate Industry

- Chemical Industry

- Pharmaceutical Industry

- Rubber Industry

- Oil & Lubricant Manufacturing

- Refineries

- Textile Industry

- Packaging Industry and Many more…

Leave A Comment