Non-pressurized Thermic fluid heaters are the most suitable heating supply equipment for modern process industries. The heat transfer medium inside these heaters is petroleum-based fluids that provide constantly maintainable temperatures for indirect process heating. Depending on the fuel they use, one can classify these Thermic fluid heaters into two types- coal/wood-fired and diesel-fired. In a coal-fired Thermic fluid heater, coal burns to heat the Thermic fluid, acting as a heat carrier. This heated fluid circulates through the user equipment, where it transfers the heat to the process through a heat exchanger and returns to the heater. Control valves operate pneumatically to vary the flow of the heat carrier, which, in turn, regulates the temperature.

Coal-fired Thermic fluid heaters usually have a thermal efficiency in the range of around 55%-65%. Commercial systems can increase the efficiency further by adding heat recovery devices. From Pharmaceuticals to textile industries, from road construction to refineries, from chemical to packaging industry, Thermic fluid heaters have several applications.

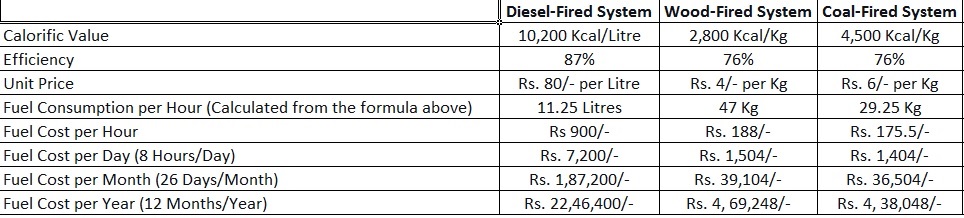

Comparison between Coal/Wood-Fired and Diesel-Fired Systems:

The calorific value of diesel and efficiency of diesel-fired systems are higher than that of wood or coal. But since the cost of diesel is 20 times more than wood and coal, the fuel cost of solid fuel-fired systems works out to be lower than diesel-fired systems. Fuel consumption of a heating system is a function of its calorific value of the fuel, and efficiency & capacity of the plant. The formula for calculating the fuel consumption of any thermal fluid heater is:

Fuel Consumption per Hour = Capacity/ (Calorific Value * Efficiency)

The table below summarizes the comparison of intrinsic thermal properties, fuel required, and savings on fuel consumption for a plant with a capacity of 1 Lakh Kcal/hr.

As shown in the table above, solid fuels can result in savings up to 80% from their equivalent diesel-fired Thermic fluid heaters.

Use of Thermic Fluid Heater in the Road Construction Industry

The road industry uses Thermic fluid heaters for Bitumen tank heating. Bitumen, having the highest boiling point, remains at the bottom of crude oil fractions. Bitumen is highly viscous, thick, sticky, and dark in color. The high viscosity of Bitumen allows asphalt, used in road construction, to remain flexible. Similarly, the heavy load-resistant property of Bitumen makes the roads durable. Due to the high elasticity of Bitumen, roads can withstand extreme temperatures and weather changes.

However, to ensure its optimal performance, Bitumen heating should be uniform, precise, and controlled. Any exposure to air or water during heating results in foaming and loss of adhesive properties. Thermic fluid heaters use indirect heating to attain high temperatures precisely and quickly, thereby offering the best conditions for road construction using Bitumen.

A typical Thermic fluid heater system for road construction consists of a heater and automatic pressure jet burners with heating coils. Thermic fluid heaters transfer the heat to the Bitumen stored in the tank through the heating coils.

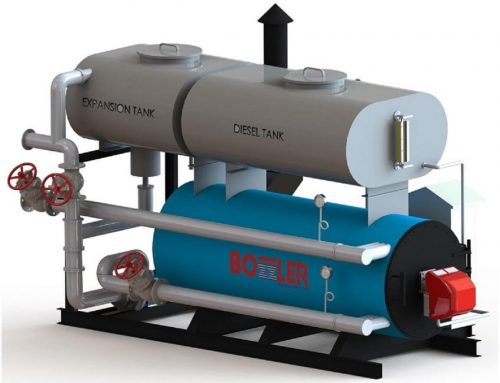

BV Series Thermic Fluid Heater

The BV Series from Bozzler Energy Pvt. Ltd. utilizes modern technology to deliver the perfect combination of the best in class efficiency and affordability. Additionally, BV Series Thermic Fluid Heaters are compact and mobile. Some of the main salient features include:

- Best in class efficiency up to 78%.

- Compact, mobile systems up to 6 lakh kcal/ hr capacity for skid-mounted systems. The capacity for non-skid systems can extend up to 10 lakh kcal/hr.

- Wood/coal-fired Thermic fluid heater systems achieve set temperatures faster than their equivalent diesel-fired systems.

- Single-day installation and commissioning of Skid Mounted Thermic Fluid Heater System.

- Low operation and maintenance cost makes the system affordable and cost-effective.

- A fully automatic system eliminates operational difficulties like high temperature, extended working hours, etc.

- An automatic system eliminates the requirement of skilled workers.

- Compatible with various fuels like wood, coal, briquette, sawdust, or any other solid fuel of similar sizes.

- Designed and tested with all safety standards with inbuilt fault detection and alarms

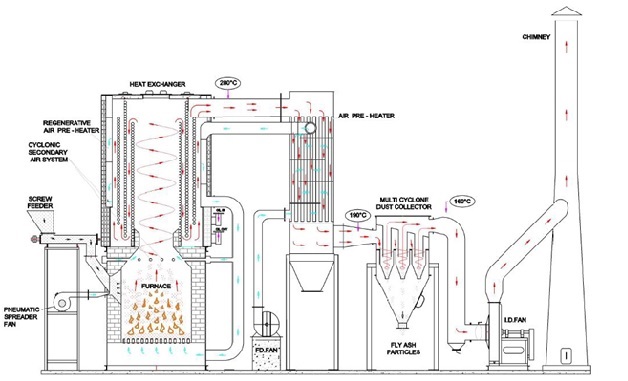

Schematic Layout of a Coal-Fired Thermic Fluid Heater System:

The figure below shows a typical coal-fired Thermic fluid heater system and its components.

The heated Thermic fluid circulates in the electrical circuit by a circulating pump. As the thermic fluid passes through the heat exchanger coils, it transfers its energy to heat the process. The regenerative air pre-heater system and dual recovery system maximize the heat recovery. The improved top-door design allows period cleaning of heater coils to minimize heat losses.

Fuels Used in Solid Fuel-Fired Thermic Fluid Heater:

Our specifically designed Thermic fluid heaters work on a variety of solid fuels offering customization and flexibility. Some of the most commonly used solid fuels are:

- Wood logs/pellets

- Coal

- Briquette

- Sawdust

- Rice husk

- Bagasse

- Petcoke

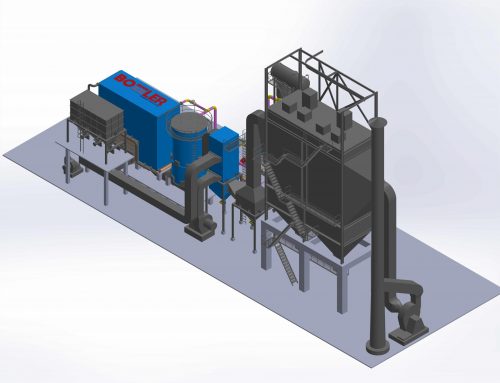

Thermic Fluid Heater Usage for Asphalt Batch Mix Plants

Asphalt Batch Mix Plants use Thermic fluid heater systems to heat asphalt cement and different equipment indirectly. Compared to the traditional, emissive, inefficient direct-fired heating, Thermionic fluid heaters allow plants to increase the storage time of prepared hot-mix asphalt. Moreover, thermic fluid heater systems, unlike steam/hot water systems, are non-corrosive.

Advantages of Coal-Fired Thermic Fluid Heater over Diesel-Fired Thermic Fluid Heater:

- Fuel handling is easy.

- The fuel cost of coal-fired Thermic Fluid Heaters is significantly lower when compared with equivalent diesel-fired systems.

- Affordable systems due to lower operational and maintenance costs

- Compact size

- Single-day installation and commissioning are possible.

Conclusion:

Thermic fluid heaters are a high-performance and efficient technique for indirect heating applications in process industries. Due to their mobility and ease of maintenance, they are perfect for road construction. Wood/coal-fired Thermic fluid heaters can attain high temperatures with minimal fuel costs and offer several advantages over diesel-fired systems. In this article, we discuss some of the important features of coal-fired Thermic fluid heaters and how you can save up to 80% by using them for road construction.

At Bozzler Energy Pvt. Ltd., we are a group of passionate people. Our experienced and well-trained professional team excels in Machine Design for Industrial Applications with social responsibilities. Our core strength lies in delivering efficient and eco-friendly burning fuels and heating equipment solutions for modern industry. Our Thermic fluid heaters have the best efficiency in the segment that boosts productivity and reduces fuel costs. Partner with us to utilize our years of experience and technical expertise for all your heating equipment and solutions.

Leave A Comment