Every manufacturing industry that produces any material from thermic fluid heaters or any other industrial equipment requires some form of process heating system. The two most common heating techniques are direct and indirect heating. Direct heating involves heating the process directly by combustion of fuels, heating filaments, or flame radiations. In indirect heating, on the other hand, a heat transfer fluid circulates between the heater and the process. While most of us at home use direct heating through stove burners or ovens, commercial industries prefer indirect heating.

Traditionally, steam boilers have dominated the process industries. However, did you know that thermic fluid heaters offer several significant advantages and can be the better option for your applications? Read on to know how you can get the maximum savings from thermic fluid heaters.

What are the Advantages of a Thermic Fluid Heater Over a Steam Boiler?

1) Cost-effective

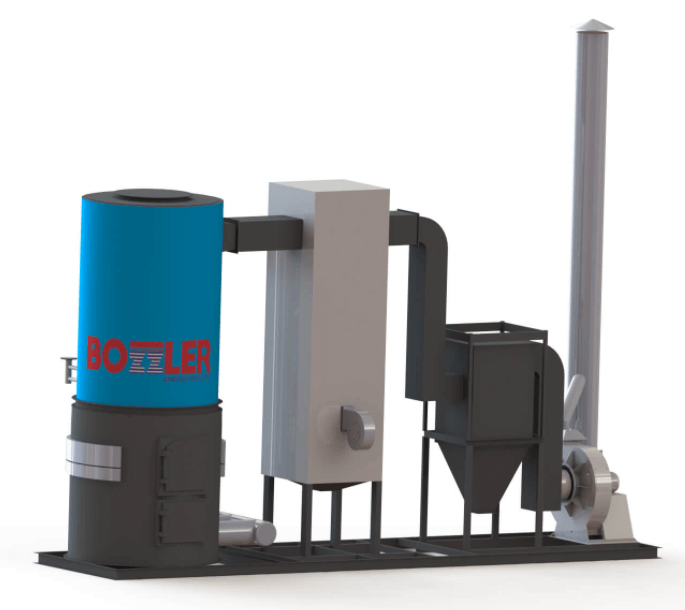

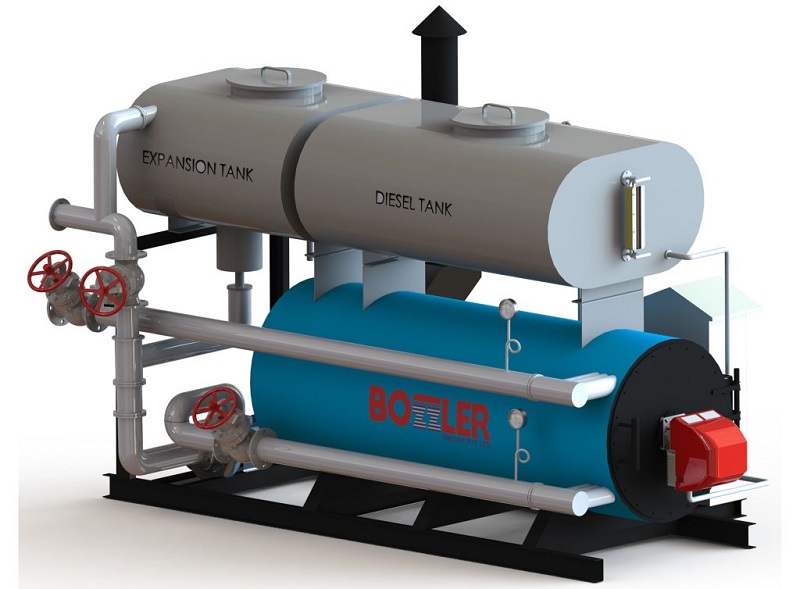

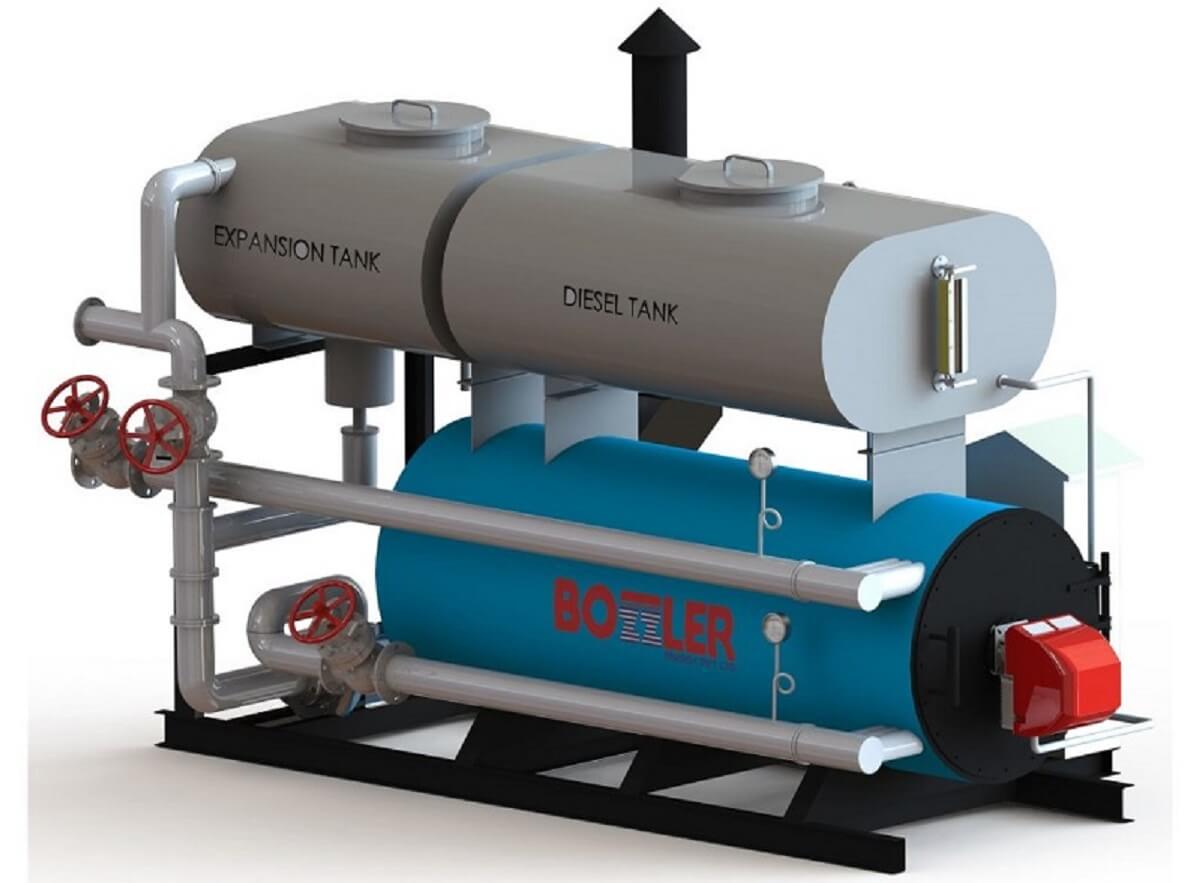

When compared with steam boilers, thermic fluid heaters cost less to install, operate, and maintain. A typical thermic fluid heating system requires a basic setup like a heater unit, pumps, and expansion tanks. Even the simplest boiler setup requires pressurized tubes, surge tanks, separators, heat recovery systems, deaerator, etc., that are costly to own and maintain. Similarly, the operational and maintenance costs to prevent corrosion of steam boiler components are significantly higher.

2) Efficient:

Due to the smaller number of components, heat losses are minimum in thermic fluid boilers. The decreased energy requirements and low operational costs result in increased profitability while being environmentally responsible.

3) Versatile:

A thermic fluid heating system can operate on several fuel types like food-grade oils, mineral oils, synthetic oils, etc. This versatility of fuel choice and operation allows you to optimize the process according to your application with better temperature control and efficiency. Moreover, you can attain higher temperatures with thermic fluid heaters without raising the pressure, which is impossible with steam boilers.

4) Require Minimum Maintenance:

Unlike steam boilers, thermic fluid heaters do not require extensive maintenance schedules to keep them running smoothly. The non-corroding, non-pressurized operation saves you from routine shutdowns for check-ups and maintenance.

5) Flexible to Install:

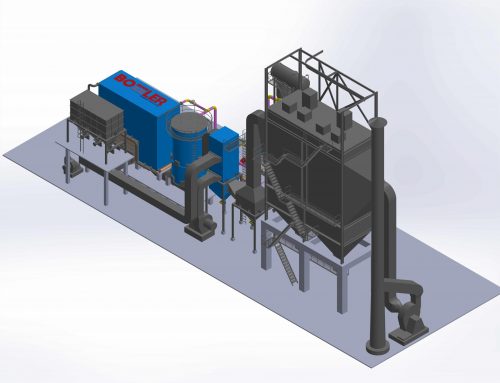

For many manufacturing industries, installing a new heating system can be a nightmare. From space constraints to lack of customization, from installation time to facility limitations, challenges are endless. With thermic fluid heaters, you can install them indoors or outdoors or retrofit them in your existing processes. Moreover, if you have limited floor space, one can even install thermic fluid heaters remotely without compromising efficiency.

6) Come with Fewer Operational Headaches:

As an owner of a manufacturing unit, thermic fluid heaters are easy to own, operate, and maintain. Steam boilers are high-pressure, high-temperature setups, and regulatory guidelines demand licensed operators or managers. On the other hand, thermic fluid heaters have fewer staff requirements and less stringent operational requirements.

7) They are Safe:

Unlike steam boilers, thermal fluid heaters are not pressurized and do not contain the risk of explosion. Similarly, thermic fluid heaters do not require anti-corrosion chemicals used in steam-based heating systems. As the thermic fluids do not freeze, they do not pose any safety hazards during cold temperatures.

How to Maintain Thermic Fluid Heaters?

Although thermic fluid boilers do not require extensive maintenance schedules, regular check-ups and prompt servicing can guarantee you trouble-free and long-lasting operation. Follow these tips to make the most of your thermic fluid heaters:

- Check the thermic fluid heater’s insulation and ensure it is in good shape for efficient heating.

- Check the piping for leaks, blockages, weak spots, etc., and repair or replace them whenever required.

- Routine visual inspection of the thermic fluid heating system can help you notice any potential areas of concern and prevent the compounding of faults.

- Schedule a yearly inspection by professionals. Take the services of a licensed technician and have him inspect your plant. Similarly, hire a burner specialist to inspect and tune your burner for maximum throughput and efficiency.

How to Improve Thermic Fluid Heater Efficiency?

The profits for any manufacturing industry depend on how efficiently they can utilize the raw materials and resources. An energy-efficient plant suffers the least from any fluctuations in energy demand and price. Moreover, an energy-efficient plant is environmentally responsible too. Here are a few ways to improve the thermic fluid heater efficiency:

1. Optimize the Pumps:

Pumps are the most energy-demanding equipment of any plant, and you must select them wisely. Similarly, a pump’s proper configuration can give you significant savings by avoiding operational costs. Here are some ways for optimizing the pumps in a thermal oil heater plant:

- Use a heat transfer fluid with high viscosity.

- Avoid throttling losses

- Implement pump’s rotation speed control

- Use pump impellers wherever you can.

2. Reduce Pressure Losses:

Pressure losses not only cause higher power consumption but also result in the non-optimized use of pumping systems. Here are some of the ways to reduce pressure losses in the different components of a thermal oil boiler:

- Use higher cross-sections in the piping to minimize the pressure loss.

- Go for pre-assembled pump systems as they have a compact design and use shorter piping lengths or distances to keep pressure losses in check.

- Larger openings or widths in pumps or fittings reduce the pressure losses.

- A generous heater design takes off the load from the heat exchanger and reduces the pressure loss effectively.

3. Use High-Quality Heat Transfer Fluids:

Higher quality heat transfer oils are ideal as they have a higher life and are more stable. Such fuels, with better heat transfer properties, shorten the production time. As the process times are shorter, production failures are less likely to occur. The reduced maintenance or repair work increases productivity by minimizing the downtime of your plant.

4. Optimize the Firing Plant:

Another way to improve the overall efficiency of the thermic fluid heaters is to optimize the firing process. Installing rotary speed controls for combustion fans can improve firing efficiency and minimize start-up losses. Similarly, minimizing exhaust gas losses, using air pre-heaters, controlling oxygen intake, etc., are a few ways to increase the efficiency of the firing process.

Conclusion:

In a nutshell, thermic fluid heaters are a sensible choice over a steam boiler system for any application. They are energy-efficient, intrinsically safe, versatile, easy to install, maintain, & operate, and have better control over temperature. Whether you are looking for an upgrade of your existing plant or installing a new one, go for thermic fluid heaters for reduced operational costs and maximum profits. Hopefully, by going through the points mentioned above, you will be able to find the perfect thermic fluid heater for your application and maintain it effortlessly.

Leave A Comment