The industrial edible oil heaters are generally used in food processing industries to heat edible oil for food preparation. The food processing machinery needs high-temperature heating of edible oil heater and to achieve that they use thermal oil heaters & heat exchangers and as an alternative fully automated re-circulation type edible oil heaters are used. These edible oil heaters are made up of stainless steel and have an extremely low heat release rate. One of the main reasons behind the popularity of edible oil heaters is that it is easy to operate and maintain. The other features of thermal edible oil heaters are high thermal efficiency, efficient use of cooking oil, rugged construction, etc.

Types of Edible Oil Heater

The thermal edible oil heaters can be classified on the basis of fuel types and that are mentioned below.

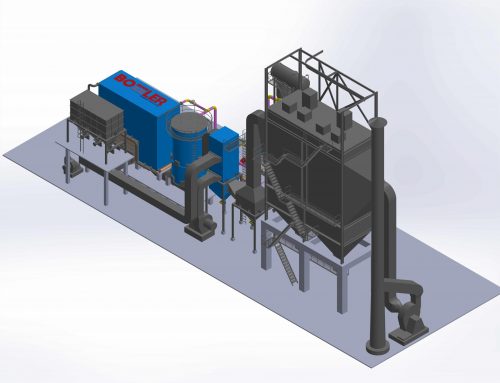

1) Solid fuel-fired Edible Oil Heater

The BEH series is a solid fuel-fired edible oil heater. It provides direct edible oil heating with around 90 percent efficiency and it has special designs to drain all the oil from the system. It is made up of stainless steel seamless SCH 40 tubes for edible oil heating. The BEH series is compatible with different fuels like LPG, Wood Pellets, light diesel oil, HSD, Natural gas, FO, etc. You can operate it at home as it is compact, pollution-free, and has a fully automatic system.

The BEH series is also compatible with all the systems including a batch fryer, chips production line, continuous fryer, etc. The solid fuel-fired edible oil heater can heat the edible oil up to 180° Celsius. The edible oil does not carbonize during heating because solid fuel-fired heaters have a very low heat release rate. These are the features of solid fuel-fired edible oil heaters.

2) Fluid Fuel Fired

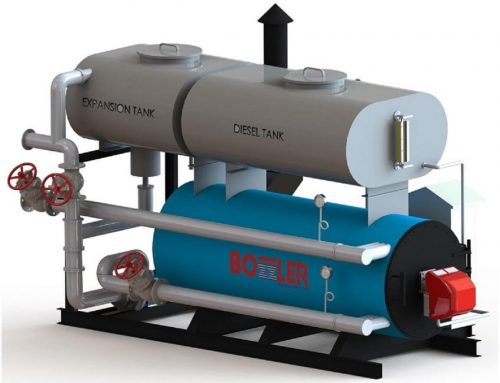

At high temperatures, water and steam need high pressure to operate. Whereas, if you use oil as the heat carrier then even at the high temperature you can operate with low pressure. The fluid fuel-fired edible oil heater provides higher efficiency as it has a large heating surface and high combustion volume.

There is no risk of corrosion because water is not used. The fluid fuel-fired edible oil heater is easy to operate and has low maintenance cost because there is no need for a certified operator. It is compatible with various fuels like natural gas, LPG, HSD, Furnace oil, etc. Overall, the fluid-fired edible oil heater has a rugged construction and offers maximum running reliability.

Features of Edible Oil Heater

The thermal fluid heating system is generally used in industrial heating. Hot oil heat has a lot of advantages and benefits over steam heat. Here, we have mentioned some of the features of edible oil heaters.

- All the equipment used in oil heating systems is non-pressurized, whereas steam heating systems require some pressure to work. Hence, there is no need of continuously monitoring and maintaining the pressure level in oil heaters and it also reduces the risk of explosions.

- The steam-based heating system uses water and in such systems, corrosion is very common. Therefore, you have to closely monitor the steam heating system for corrosion. In an oil heater, you do not have to worry about corrosion as it works as a lubricant and runs smoothly in the system.

- Normally in heating systems chemicals are used in order to avoid corrosion. In oil heaters, there is no need for chemical regulation and the heating fluid runs in a loop in the system. The steam heating system needs to be treated with various chemicals because of corrosion and these chemicals should be monitored and regulated carefully to make sure that the system is working effectively.

- Oil heaters can work at higher temperatures: Oil has a higher boiling point and because of this oil heaters can operate at higher temperatures. Operating temperature is very important for efficient heating. At high temperatures, you get better performance of heating equipment. Oil heaters can work in higher temperatures and there is no need for additional pressure.

- One of the biggest advantages of using an oil heater is that the fluid will not freeze. Hence, there will be no issues or problems related to cold temperatures. Water can freeze and this can cause issues in the boiler system and that is why oil heaters are beneficial.

- Normally, when a steam boiler is working it is necessary to have a licensed boiler staff. These rules and regulations can affect the selection of heat processing equipment. If you are using the oil heating system, then there is no need to add a new member. This makes the oil heaters easy to operate and it saves money and resources.

- From a safety point of view, hot oil systems are better than steam heating systems. There are various reasons that make hot oil systems safe like there is no need for pressurization and this removes the risk of explosions. Also, the cold temperature would not cause any problems because the freezing point of hot oil is very low.

- The oil heater is very efficient, and the operating cost is also very low. They are easy to use and it saves a lot of money and resources. The hot oil heating system only needs a pump, heater, and an expansion tank, whereas a boiler system has a lot of components like chemical feed tanks, deaerators, steam traps, condensate tanks, blowdown tanks, etc.

The additional features of edible oil heaters are their efficiency and safety. These are some of the various benefits of Edible oil heaters.

Leave A Comment